Many decisions go into choosing the proper uninterruptible power supply (UPS): power requirements, runtime, battery technology, physical size, installation location, efficiency, environmental impact, etc. We’ve covered many of these topics in previous power articles.

However, there is one basic question that often gets overlooked: should you install a conventional UPS or a modular UPS?

This article explores the differences in UPS construction, including the pros and cons of each format and the typical applications where each are installed. Additional information on actual UPS models is available on the Xtreme Power Conversion product page.

Modular vs. Conventional: What’s the Difference?

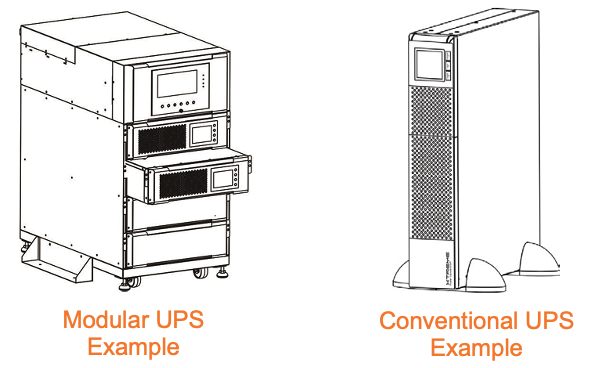

A modular UPS is made up of independent power modules that can be added and removed to scale power needs and perform service, whereas a conventional UPS is a single fixed unit. Modular UPSs are typically installed in environments with growing and/or fluctuating power needs and applications where uptime performance is critical. Often, whole building and centralized UPS systems leverage modular technology.

Conventional UPSs, on the other hand, are typically installed in smaller applications where scalability and mission-critical performance isn’t a concern. Many point-of-service UPSs follow a conventional fixed design.

Modular vs. Conventional: Key Differences

Modular and conventional UPS constructions have several key differences, including scalability, flexibility, redundancy, serviceability and cost.

Scalability. Modular UPS systems can be easily expanded by adding more modules as power requirements grow, whereas conventional UPS systems typically require replacing the entire unit to increase capacity.

Flexibility. Modular UPS systems can be customized to specific power needs by combining different modules, whereas conventional UPS systems are typically fixed to a specific connection and power type.

Redundancy & Reliability. Modular UPS systems can be configured with redundant battery modules to ensure continuous power even if one or more modules fail, whereas conventional UPS systems are reliant only on their main battery modules. Mission-critical systems almost always rely on modular UPS technology.

Maintenance. The redundant battery modules in modular UPS systems also provide backup when the system is being repaired or upgraded, whereas conventional systems require shutting down the entire UPS for maintenance ultimately leaving the equipment downstream unprotected.

Energy Efficiency. Modular UPS systems can be configured specifically for the intended application, ensuring efficient operation and optimal performance. Conventional UPS systems, on the other hand, operate at a fixed capacity regardless of application, leading to inefficient operation and potentially battery damaging discharge patterns.

Cost. The upfront cost of modular UPS systems does tend to be higher than conventional UPS systems, as flexible and scalable hardware is required. However, the long-term cost of modular UPS systems can be equal to or even less than conventional systems thanks to decreased maintenance costs and, if needed, replacements and upgrades.

Modular vs. Conventional: The Right Decision

So what’s the right choice: modular UPS or conventional UPS? Well, it really depends on budget and application.

Fixed deployments with tight budgets will typically benefit from the lower cost of a conventional UPS system; however, systems that anticipate growth and depend on reliable long-term operation will benefit from modular systems. To simplify things, we can sum the decision as follows:

- Fixed point-of-service installation: conventional

- Upfront price sensitive: conventional

- Whole-building centralized installation: modular

- Long-term overall value: modular

- Ease of system scaling and flexibility: modular

- Ease of system maintenance: modular

- Mission-critical system reliability: modular

- Energy efficiency: modular

The good news is Future Ready Solutions offers both conventional and modular UPS systems in a variety of formats and constructions. Additional information is available on the Xtreme Power Conversion product page or by contacting us for design assistance.