As we’ve explained in previous articles, fiber optic cable comes in a variety of configurations and constructions. We’ve explored the pros, cons and applications for both single mode and multimode fiber, and we’ve discussed the differences between traditional fiber and Cleerline SSF™.

However, another key attribute of any fiber optic integration is what cable construction to use.

The below article discusses common fiber optic jacket ratings, as well as the actual construction of popular cable formats. We’ll discuss the environment and application where each format is typically deployed, including the pros and cons installers often face.

Additional information on fiber optic cables, connectors, connectivity and installation best practices is available in the Future Ready Solutions News & Insights Library.

Jacket Compounds

Before we examine the physical construction of common fiber optic cables, it’s important to understand the compounds that cable jackets are manufactured with as well as their ratings and intended applications. As with other low-voltage cables, a cable’s jacket rating will determine whether it can be installed within walls, above and below living spaces, or in an outdoor environment.

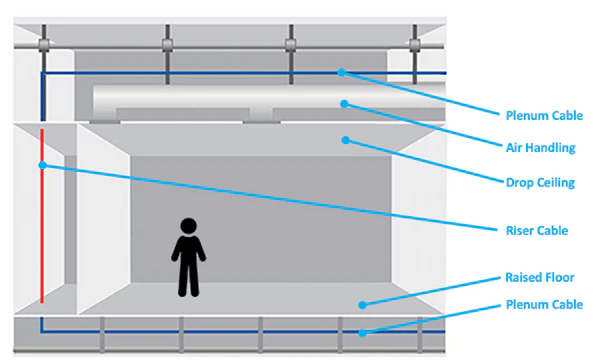

Riser Rated (typically denoted as CMR, CL2R or CL3R). Riser rated cables tend to be the least expensive cable format. They are typically used for wiring in vertical spaces from floor-to-floor and have a basic fire rating. Riser rated cables are widely used in both commercial and residential installations.

Plenum Rated (typically denoted as CMP, CL2P or CL3P). Plenum rated cables are usually more expensive than riser rated cables. They are typically required by building code in plenum spaces above drop ceilings or below raised floors, especially in multiunit residential and commercial buildings. Plenum rated cables have a higher fire rating than riser cables. Plenum rated cables can go in riser spaces, but riser rated cables cannot go in plenum spaces.

Low Smoke Zero Halogen Rated (typically denoted as LSZH). Low smoke zero halogen rated cables are similar to plenum with fire rating, but they emit limited smoke and no halogen when exposed to heat. They are commonly found in Europe and in marine vessel construction (such as yacht building).

Outdoor Rated. A cable with an outdoor rating is designed for UV and water exposure. Outdoor rated cables are typically installed in conduit or corrugated pipe outdoors; however, they are not recommended for direct burial in soil because they lack protective armor. A plenum, riser or low smoke zero halogen rated cable can also have an outdoor rating.

Armor

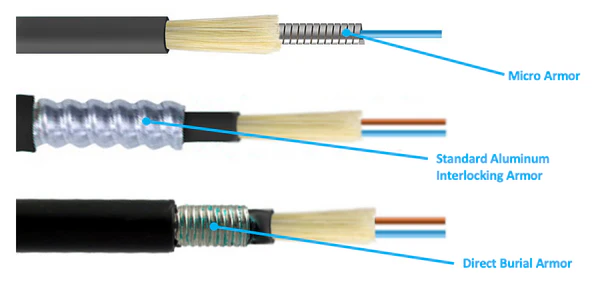

Armoring is another key consideration when choosing a fiber cable. Armor provides protection against abrasion, chewing from rodents, cutting and crushing; however, it also adds significant weight and affects a cable’s flexibility. It’s important to choose the proper armor for the intended application.

Standard Armor (AIA). Armored cables rated for indoor installations typically leverage aluminum interlocking armor (also known as AIA). These cables are built in a distribution format with multiple fiber strands within a single jacket. Armored cables are significantly heavier, thicker and less pliable than non-armored cables; however, their armor make them ideal for exposed cable runs and environments with rodent activity.

Micro Armor. Micro armored cables deliver the strength of traditional AIA armoring with the pliability and size of a non-armored cable. Their secret is an ultra small helical stainless steel armor which permits tight bends while still protecting the internal fiber optic strands. Micro armor commands a premium price and it’s not typically terminated in the field. Consider a factory-terminated premade cable if micro armoring is required.

Direct Burial Armor. Direct burial cables are also armored and are designed for direct burial in soil. Typically they are trenched between buildings or outdoor cable vaults. Unlike AIA and micro armored cables, direct burial cables feature a solid waterproof inner sheath that protects the fiber from moisture, heat, soil acidity and other outdoor element exposure. Most direct burial cables are built with stainless steel.

Cable Constructions Typically Installed Indoors

There are several constructions of cable that are commonly installed in indoor, environmental controlled applications.

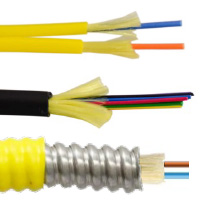

Duplex. Duplex (also known as siamese or zip-cord) cables feature two strands of fiber that are individually jacketed and connected with a central membrane.

Duplex. Duplex (also known as siamese or zip-cord) cables feature two strands of fiber that are individually jacketed and connected with a central membrane.

Duplex cables are typically used for patching in shorter lengths; though many integrators choose to integrate duplex fiber in prewires because it’s easy to terminate and robust for handling and connections.

The two strands in duplex are typically the minimum required for network and audio-visual signal distribution, and most wallplates, patch panels and SFP transceivers feature duplex connections.

Distribution. Distribution cables features multiple strands of fiber within a single outer jacket. Depending on the application, the strand counts can get very high and manufacturers such as Cleerline support distribution cables up to 288 total fibers.

Distribution. Distribution cables features multiple strands of fiber within a single outer jacket. Depending on the application, the strand counts can get very high and manufacturers such as Cleerline support distribution cables up to 288 total fibers.

Distribution cables are ideal for multi-signal distribution, such as from rack-to-rack or floor-to-floor, and they are available in a variety of formats including simplex (one strand), standard (multiple strands in a 900um construction) and micro (multiple strands in a 250um construction). Cleerline manufacturers micro distribution format cables because of the robustness of their SSF™ fiber.

Aluminum Interlocking Armored. Aluminum interlocking armored (AIA) cables feature multiple strands of fiber and overall metal armoring within a single outer jacket. AIA cables are essentially distribution cables with the added strength of aluminum armor.

AIA cables are ideal for environments with rough installations, exposed cable paths, rodents and other potential sources of abrasion, wear or damage.

AIA cables are commonly available in strand counts up to 144 total fibers.

Double Jacket Micro Distribution. Double jacket micro distribution (DJMD) cables provide a stronger alternative to standard distribution constructions without the bulkiness of armor. They feature a second outer jacket for increased durability, pull tension and protection.

Double Jacket Micro Distribution. Double jacket micro distribution (DJMD) cables provide a stronger alternative to standard distribution constructions without the bulkiness of armor. They feature a second outer jacket for increased durability, pull tension and protection.

DJMD cables are ideal for ducts, riser spaces and tray installations where abrasion during and after the installation is a concern. They also feature an indoor/outdoor rated jacket and water blocking yarns, allowing for the transition between indoor and outdoor environments without the need for junction boxes and enclosures.

Breakout. Breakout cables feature the single jacket construction of a traditional distribution cable with strengthened internal subunits similar to unzipped duplex cables.

Breakout. Breakout cables feature the single jacket construction of a traditional distribution cable with strengthened internal subunits similar to unzipped duplex cables.

Breakout cables are an ideal solution for room-to-room prewires and quick connections because they don’t require build-up hardware such as fan-out kits or breakout kits — you simply terminate connectors to each individual strand.

Cleerline manufactures breakout cables in four strand constructions using multimode OM3 fiber — a common choice for both residential and commercial building infrastructure applications.

Cable Constructions Typically Installed Outdoors

In addition to indoor constructions, fiber optic cable is widely available in both indoor/outdoor and outdoor-only constructions.

Outdoor Distribution. Similar to indoor distribution cables, outdoor distribution cables features up to 288 strands of fiber within a single outer jacket. However, unlike their indoor counterparts, outdoor distribution cables feature a UV and water-rated jacket, as well as water blocking yarns for enhanced protection and durability when exposed to wet and humid environments.

Outdoor Distribution. Similar to indoor distribution cables, outdoor distribution cables features up to 288 strands of fiber within a single outer jacket. However, unlike their indoor counterparts, outdoor distribution cables feature a UV and water-rated jacket, as well as water blocking yarns for enhanced protection and durability when exposed to wet and humid environments.

Outdoor-rated distribution cables are typically installed in conduit, duct or other protected raceways, as their thin jackets won’t stand up well to impact, abrasion or rodents.

As with other outdoor-rated cables, outdoor distribution cables are typically colored black.

Rugged Outdoor Distribution. Rugged outdoor distribution cables expand on the standard distribution cable construction with a thickened outer jacket, internal water blocking tape layer and central PVC sleeve.

Rugged Outdoor Distribution. Rugged outdoor distribution cables expand on the standard distribution cable construction with a thickened outer jacket, internal water blocking tape layer and central PVC sleeve.

This “ruggedized” construction provides superior weather protection, rodent protection and strength while ensuring lightweight flexibility.

Rugged outdoor distribution cables are often stapled in place in above ground applications; however, they are not rated for the stressors of direct burial applications. Cables placed underground or directly in soil require a direct burial rating.

Armored Direct Burial. Armored direct burial cables are designed for soil exposure and underground installation without the need for conduit, duct or other protective raceways.

Armored Direct Burial. Armored direct burial cables are designed for soil exposure and underground installation without the need for conduit, duct or other protective raceways.

Available in strand counts up to 24 total fibers, armored direct burial cables feature corrugated steel armor and a UV and water-rated jacket.

In addition to underground applications, armored direct burial cables also support aerial installation when lashed to an overhead line, wire or strength member.

Duplex Hybrid Demarc. Duplex hybrid demarc cable is exclusively manufactured by Cleerline and is designed for interior and exterior telecommunication and broadband applications. Its physical construction is similar to a traditional duplex cable — two fiber strands are connected with a central membrane. However, the two strands are not the same type of fiber — one is Cleerline SSF™ single mode and the second is traditional bend-insensitive single mode.

Duplex Hybrid Demarc. Duplex hybrid demarc cable is exclusively manufactured by Cleerline and is designed for interior and exterior telecommunication and broadband applications. Its physical construction is similar to a traditional duplex cable — two fiber strands are connected with a central membrane. However, the two strands are not the same type of fiber — one is Cleerline SSF™ single mode and the second is traditional bend-insensitive single mode.

This hybrid construction lends itself to prewires where different (and often undecided or unknown) connector and termination styles will be used.

Duplex hybrid demarc cable is an ideal choice for both residential and commercial installations where a service provider will connect fiber broadband at a later date.

Additional information on the above fiber optic cable constructions, including pricing and specification information, is available from the Future Ready Solutions website.