Fiber optic cabling comes in a variety of configurations and constructions: multimode, single mode, simplex, duplex, distribution, etc. You can find these variants on the Future Ready Solutions website, including articles and case studies detailing where each is used.

However, another core consideration is whether to use fiber cabling built with a traditional glass construction or a Cleerline SSF™ glass-encapsulated-by-polymer construction. Both are available from Future Ready Solutions, and both have their place in fiber optic installations.

This article explores the differences between the two, including the applications and use cases where each provide value.

Additional information, including articles on cable jacketing, connectors, tools, testers and other design, installation and troubleshooting best practices, is available in the Future Ready Solutions News & Insights Library.

Traditional Fiber Optic Cabling

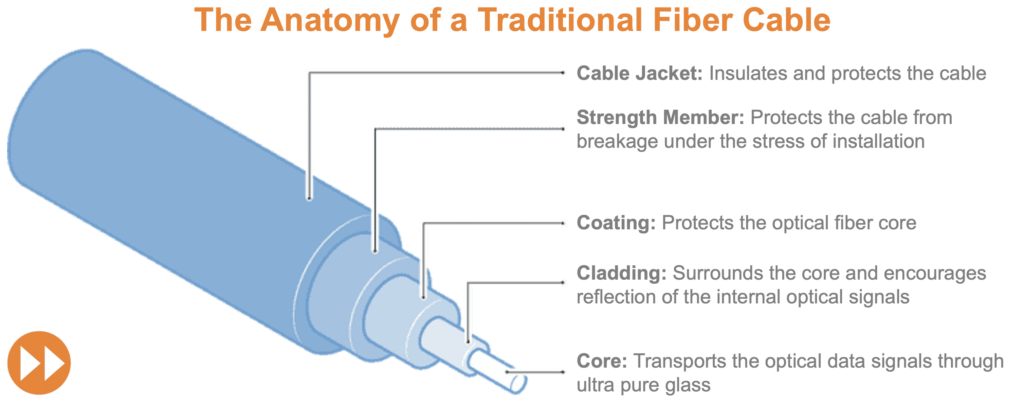

Fiber optic cabling is traditionally built with five different construction layers:

- Cable jacket — the outer covering that insulates and protects the cable

- Strength member — the aramid or Kevlar yarn that strengthens and protects the cable from breakage (especially during installation and pulling)

- Coating — the internal covering that protects the optical core

- Cladding — the internal reflective surface that encourages light propagation

- Core — the glass strand that transports optical laser and LED signals

Depending on the installation environment, armoring and waterproofing may also be used; however, the core components tend to remain the same: jacket, strength member, coating, cladding, core.

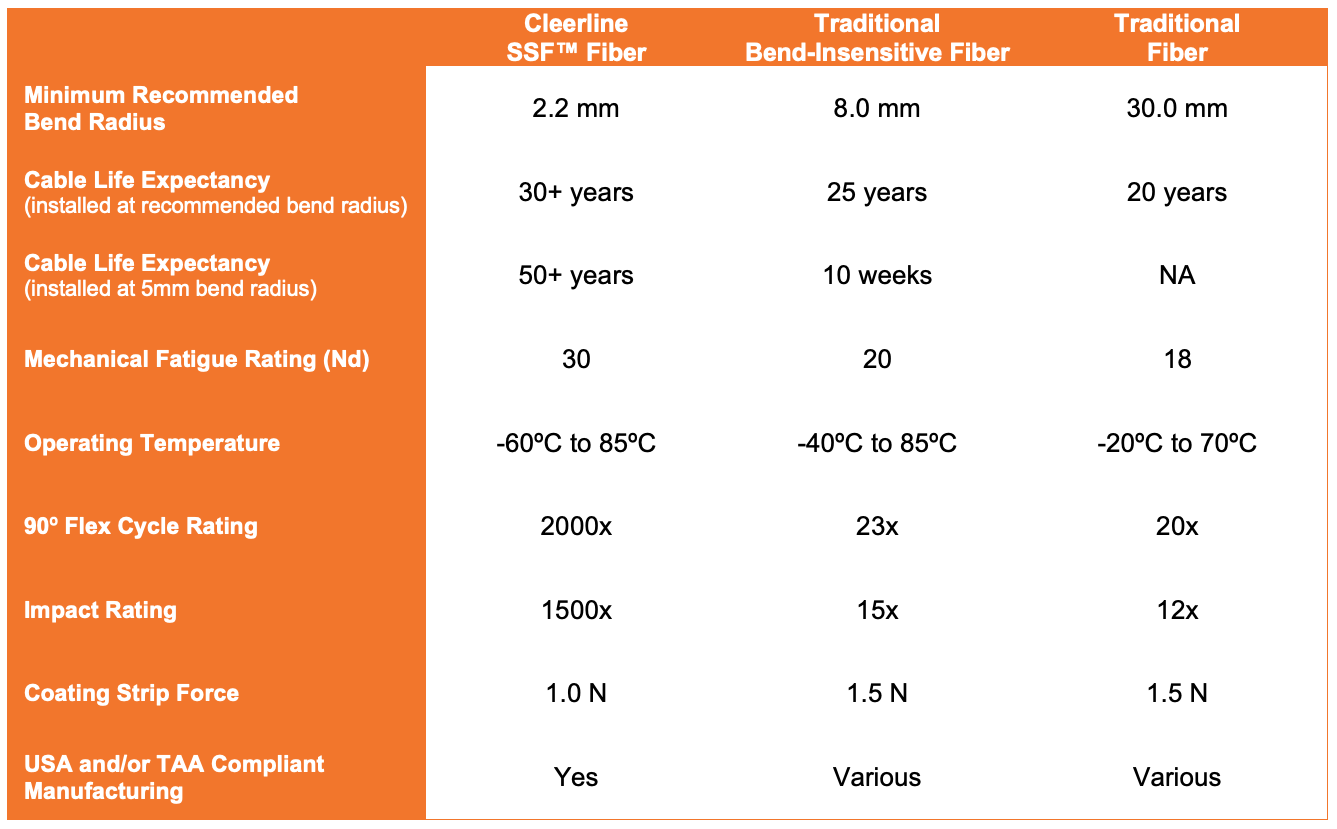

Traditional fiber optic cables employ a core built with ultra pure glass designed to balance performance and flexibility. The glass in older cables could survive bends and kinks up to 30mm (or 1.2 inches) without breaking; whereas newer “bend-insensitive” cables survive bends and kinks up to 8mm (0.3 inches) without breaking.

And in the fiber world, it’s all about breakage and optical integrity….. a broken, crushed or cracked core will impede signal performance rendering the cable unusable. It’s imperative that traditional fiber optic cables be handled and installed properly within their stated specifications.

Cleerline SSF™ Fiber Optic Cabling

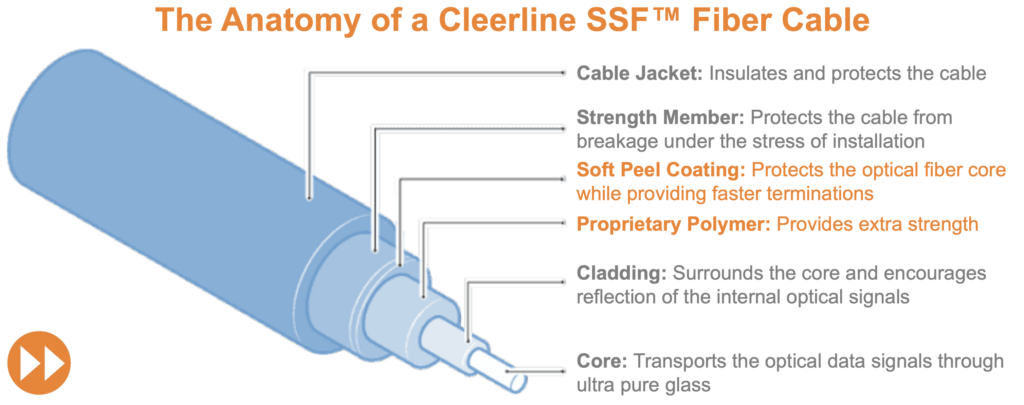

Unlike traditional fiber which is constructed of glass, Cleerline SSF™ leverages a patented glass-encapsulated-by-polymer design that significantly increases optical strand strength while eliminating contaminant access points. SSF™ delivers a stronger, more flexible cable that’s thinner and easier to terminate in the field.

Simply put: cables built with SSF™ out bend, out handle and outlast traditional cable technology even in extreme applications, environments and installation paths without affecting signal performance.

A common misconception around SSF™ technology is that the glass-encapsulated-by-polymer design doesn’t conform to industry standards and can’t be used with traditional tools, testers, connectors and connectivity equipment. This is false: all Cleerline SSF™ cable constructions comply with standards and are compatible with common tools, connectors, patch panels, couplers and other enclosure and connectivity hardware. In fact, SSF™ cables actually terminate faster and more reliably than traditional cables due more durable handling and an easier-to-prepare proprietary soft peel coating.

However, this premium performance does come at a price, and Cleerline SSF™ cables tend to be more expensive than cables built with a traditional glass construction.

Additionally, installers who fusion splice cables and connectors often find the installation process longer with a Cleerline SSF™ cable due to the added steps of removing the proprietary soft peel coating and polymer. SSF™ lends itself to in-the-field mechanical connectors (which are commonly used in the audio-visual and security industries).

What’s Better?

So what’s better: cables built with a traditional glass construction or those build with a Cleerline SSF™ glass-encapsulated-by-polymer construction? Well, it really depends on your application and installation constraints.

- Price — traditional cable tends to be less expensive

- Durability — SSF™ outperforms with significantly better fatigue, flex, impact and operating temperature ratings

- Life expectancy — SSF™ outperforms with a significantly longer life expectancy, even with tight and problematic cable paths

- Ease of installation — SSF™ is easier to install when using in-the-field mechanical connectors, whereas traditional cable has an edge when fusion splicing

- Available options — traditional cable has a much wider array of constructions and configurations due to the adoption by virtually all manufacturers (other than Cleerline, of course)

So that said, Future Ready Solutions tends to make the following recommendations when trying to decide between traditional fiber optic cabling and Cleerline SSF™:

- If you’re new to fiber — SSF™ offers an easier installation experience

- If you only install fiber occasionally — SSF™ is more forgiving with less installation steps

- If you have a harsh installation — SSF™ provides better temperature and flexibility ratings

- If your installers are rough on cable — SSF™ is more durable

- If you’re fusion splicing connections — traditional cable is easier and faster to fusion splice

- If you’re purchasing pre-made or factory terminated cables — traditional cable is less expensive, especially considering the termination labor was performed at the factory

- If you’re installing cable used for a broadband connection — traditional fiber is required for broadband and telecommunication applications (our News & Insights Library has more on this topic)

The team at Future Ready Solutions will help you work through the fiber optic cable selection process. Additional information is available online.