Fiber optic tools are very different than those used for coax, twisted pair and other copper-based cables. Fiber requires a level of precision when stripping, cleaving and preparing optical strands to ensure clean connections and pure light propagation.

The below article explores the tools commonly used to integrate and terminate fiber optic cable and connectors. The Future Ready Solutions Tools & Test Equipment collection explores these solutions in greater detail.

Our News & Insights library is also a wealth of knowledge, and we offer articles that delve deeper into fiber optic testers, the difference between mechanical splicing and fusion splicing, and a variety of other fiber-related topics.

But before we begin, it’s important to understand why quality tools are necessary.

Why Quality Tools are Necessary

Fiber optic installations depend on the clean transfer of light from end-t0-end. Quality tools that are specifically designed and precision manufactured for fiber cable ensure the optical strand remains intact during the rough handling of an installation.

Failure to use quality tools can lead to the damage of the optical strand and, in turn, disrupt the flow of light limiting bandwidth and distance.

Ironically, the best scenario with damaged cable is a complete lack of performance — we know it’s broken and we can identify and repair the break. However, in many cases, the cable still passes light (though limited) and the performance degrades over time. These scenarios are much harder to troubleshoot and they often lead to the complete replacement of the cable.

Common Fiber Optic Tools

The below tools are commonly used for integrating and terminating fiber optic cable. These tools are available individually or in complete tool kits.

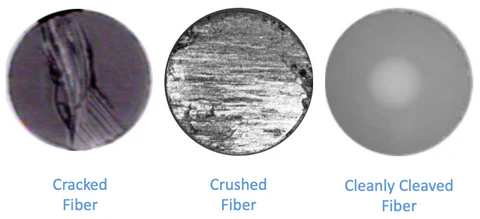

Cleaver. The precision wheel cleaver cleanly cuts (or “cleaves”) the fiber optic strand. A high-quality cleaver essentially scores and snaps the glass strand, ensuring a clean transmitting surface. Cleaving the fiber strand during termination is essential because other preparation tools, including the sheers and stripper described below, will crush and/or crack the glass during normal use.

Cleaver. The precision wheel cleaver cleanly cuts (or “cleaves”) the fiber optic strand. A high-quality cleaver essentially scores and snaps the glass strand, ensuring a clean transmitting surface. Cleaving the fiber strand during termination is essential because other preparation tools, including the sheers and stripper described below, will crush and/or crack the glass during normal use.

View full cleaver details, including pricing and availability, here.

Explore the cleaver in complete tool kits here.

Sheers. Fiber optic kevlar and aramid yarn sheers are used for cutting fiber optic cables. Optical cables are surprisingly strong and kevlar sheers are essential for trimming the cable from the spool and cutting cables to length. A good sheers features a stainless-steel micro-serrated blade.

Sheers. Fiber optic kevlar and aramid yarn sheers are used for cutting fiber optic cables. Optical cables are surprisingly strong and kevlar sheers are essential for trimming the cable from the spool and cutting cables to length. A good sheers features a stainless-steel micro-serrated blade.

View full sheers details, including pricing and availability, here.

Explore the sheers in complete tool kits here.

Strippers. Fiber optic strippers remove the outer jacket and inner strand coatings from the fiber optic cable. Most strippers are available with three holes: the largest hole is designed for the outer cable jacket, the middle hole reduces the inner 900µm buffer to 250µm, and the smallest hole reduces a 250µm strand to 125µm. Actual use will be dictated by the cable and connectors you are working with (most fiber tools are universally compatible with a variety of different cable and connector types).

Strippers. Fiber optic strippers remove the outer jacket and inner strand coatings from the fiber optic cable. Most strippers are available with three holes: the largest hole is designed for the outer cable jacket, the middle hole reduces the inner 900µm buffer to 250µm, and the smallest hole reduces a 250µm strand to 125µm. Actual use will be dictated by the cable and connectors you are working with (most fiber tools are universally compatible with a variety of different cable and connector types).

View the different options for strippers, including pricing and availability, here.

Explore the striper in complete tool kits here.

Slit & Ring Stripper. The slit and ring stripper provides the precise stripping of fiber optic cables by cutting the jacket in a circumference (also known as a spiral or ring cut) and allowing it to be pulled off. Designed specifically for the tolerances of fiber, the slit and ring stripper ensures the inner strands are not damaged during the installation process.

Slit & Ring Stripper. The slit and ring stripper provides the precise stripping of fiber optic cables by cutting the jacket in a circumference (also known as a spiral or ring cut) and allowing it to be pulled off. Designed specifically for the tolerances of fiber, the slit and ring stripper ensures the inner strands are not damaged during the installation process.

View full slit & ring stripper details, including pricing and availability, here.

Explore the stripper in complete tool kits here.

Radial Stripper. Similar to the slit and ring stripper, the radial stripper also cuts fiber optic cable jackets in a circumference and allowing it to be pulled off. However, the radial stripper supports much thicker multi-strand cables up to 1 inch in diameter.

Radial Stripper. Similar to the slit and ring stripper, the radial stripper also cuts fiber optic cable jackets in a circumference and allowing it to be pulled off. However, the radial stripper supports much thicker multi-strand cables up to 1 inch in diameter.

View full radial stripper details, including pricing and availability, here.

Explore the stripper in complete tool kits here.

Visual Fault Locator. The visual fault locator, or VFL, generates a visible red laser which transmits through the fiber optic cable and connectors. It’s essential for showing signal continuity and, depending on the type of connectors, can be used to troubleshoot termination. The VFL is also useful for finding out-of-spec cable bends and breaks because the red light is often visible through an overly torqued cable jacket.

Visual Fault Locator. The visual fault locator, or VFL, generates a visible red laser which transmits through the fiber optic cable and connectors. It’s essential for showing signal continuity and, depending on the type of connectors, can be used to troubleshoot termination. The VFL is also useful for finding out-of-spec cable bends and breaks because the red light is often visible through an overly torqued cable jacket.

Most VFLs are natively compatible with 2.5mm ferrule connections, such as SC, ST and FC-style connectors. LC connectors require a VFL adapter.

View full visual fault locator details, including pricing and availability, here.

Explore the visual fault locator in complete tool kits here.

Visual Fault Locator Adapter. The VFL adapter adapts a 2.5mm ferrule (such as those in SC, ST and FC connections) to the 1.25mm ferrule size used in LC connectors.

Visual Fault Locator Adapter. The VFL adapter adapts a 2.5mm ferrule (such as those in SC, ST and FC connections) to the 1.25mm ferrule size used in LC connectors.

VFL adapters are available in different constructions; however, those with a barrel design are made for installing mechanical connectors with sliding tabs and click buttons.

View full visual fault locator adapter details, including pricing and availability, here.

Explore the visual fault locator adapter in complete tool kits here.

Cleaning Pen. Pen-style, or “click” style, fiber optic cleaners are used to clean up to 95% of contaminants from the optical lenses in connectors, couplers, adapters and electronics’ ports. They are far more effective than traditional swab cleaning rods and alcohol wipes. Most cleaners are rated for 800 – 1000 clean cycles and they are specific to either 2.5mm (SC, ST, FC) or 1.25mm (LC) ferrules.

Cleaning Pen. Pen-style, or “click” style, fiber optic cleaners are used to clean up to 95% of contaminants from the optical lenses in connectors, couplers, adapters and electronics’ ports. They are far more effective than traditional swab cleaning rods and alcohol wipes. Most cleaners are rated for 800 – 1000 clean cycles and they are specific to either 2.5mm (SC, ST, FC) or 1.25mm (LC) ferrules.

View the different options for cleaning pens, including pricing and availability, here.

Explore the cleaning pen in complete tool kits here.

Pull Eye. Pulling eyes, also known as pulling socks, are critical for installing fiber optic cable. They ensure the integrity of the cable and any pre-installed connectors during the fiber pull. Failure to use a pulling eye can result in stretched jackets and broken strands.

Pull Eye. Pulling eyes, also known as pulling socks, are critical for installing fiber optic cable. They ensure the integrity of the cable and any pre-installed connectors during the fiber pull. Failure to use a pulling eye can result in stretched jackets and broken strands.

View the different options for pulling eyes, including pricing and availability, here.

Pulling eyes are not typically available in fiber tool kits. They are sold separately due to the wide availability of styles and options.