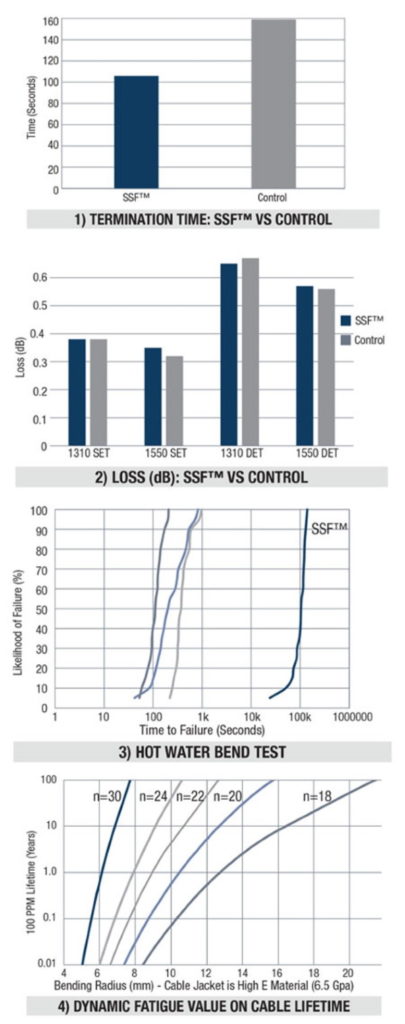

SSF™ Fiber is far simpler to terminate because the bare fiber is never exposed, and SSF™ soft peel coating is far easier to remove than traditional fiber’s hard acrylate layer. In our 2014 case study, certified fiber technicians trained to work with traditional fiber were able to terminate SSF™ in an average time of 106 seconds.

That’s after only 10 minutes of instruction on how to work with SSF™. Comparatively, traditional fiber took an average of 159 seconds to terminate, or 33% longer. We’re confident that after more opportunities to work with SSF™, termination times would decrease even further. The case study also showed that after minimal training, technicians were able to achieve nearly identical attenuation rates with SSF™.

Loss measurements for SSF™ were within 0.03 decibels (dB) of the loss measurements for traditional fiber when tested via single and double ended testing (fig. 2).

Not only is SSF™ simpler to terminate, it is extremely resilient under difficult conditions. In one test, both SSF™ and traditional fibers were bent to a radius of 3 to 3.5 mm between two metal plates and submerged in 90°C water to simulate extreme conditions.

As demonstrated in the Figure 3, SSF™ took nearly 40 hours (130,000 seconds) to reach a 100% chance of failure. The nearest competitor took only approximately 16 minutes to reach a 100% failure rate.

SSF™ can tolerate a great deal of stress with little chance of failure, meaning enhanced security for installations. Furthermore, under the IEC60793-1-33 standard for fiber optics, fiber is tested to determine the dynamic and static fatigue values for the fiber, indicating how well fiber will last over time.

Currently, demonstrating a dynamic fatigue value (n) of 18 is recommended for industry fiber. Under testing, SSF™ shows a dynamic fatigue value of n=30 (fig. 4).

According to the ITU-T Series G recommendations for fiber reliability, a higher n value indicates higher tolerance to strain. As demonstrated in the graph (fig.4), n=30 fibers like SSF™ are able to tolerate smaller bend radii under tension for a longer a period of time. The bottom line? The enhanced strength of Cleerline SSF™ means that installations will be built to last.