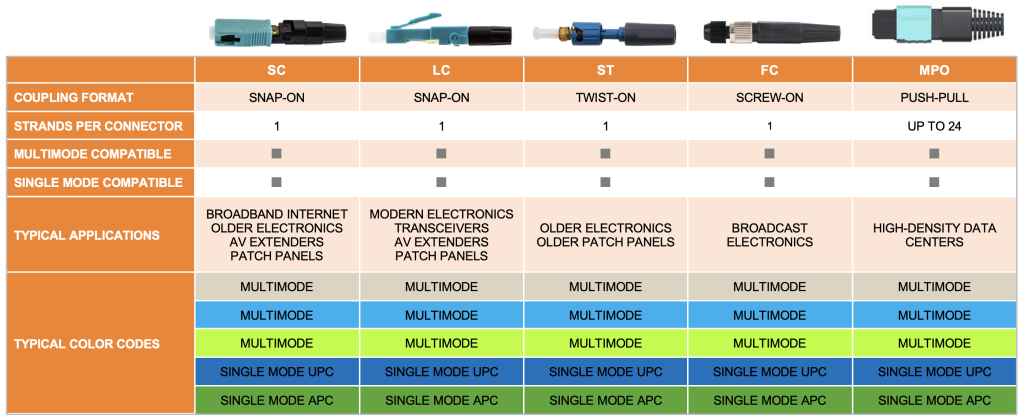

Fiber optic connectors are available in a variety of formats depending on the cable type and connection style. This article explores the connectors commonly used in audio-visual, networking, broadcast, broadband internet and other low-voltage applications.

Before We Begin: Understanding Connector Polish

Fiber optic cable typically follows an industry-standard color code: a yellow jacket denotes single mode, an aqua jacket denotes multimode OM3, an orange jacket denotes multimode OM2, etc. But what about the connectors? What’s the difference between blue connectors and green connectors? After all, both find their way onto single mode and, selectively, multimode cable.

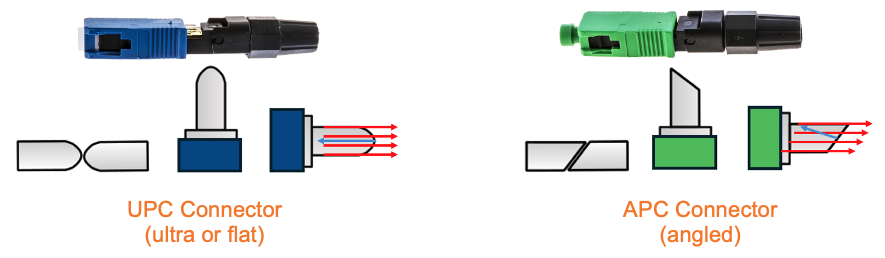

The answer has to do with the connector endface polish, or the angle of connection, and the good news is connectors also follow industry-standard color codes. Aqua, beige, lime green and blue denote a straight through (also known as a flat or UPC) polish and dark green denotes an angled (or APC) polish.

The angle of polish is important and UPC connectors should not be mixed with APC connectors. Generally speaking, best practice is to match the color of the connector to the color of the electronic’s or connectivity hardware’s port.

APC connectors are polished at an 8 degree angle, while UPC connectors are polished with no angle, though they do have a slight curvature to ensure better optical core alignment. Why the difference? An angled construction provides less overall loss and is ideal for outside plant, demarcation wiring, internet broadband and other high optical wavelength applications.

In practice, you’ll typically see APC connectors integrated before the modem and UPC connectors after the modem.

LC Connectors

Developed by Lucent Technologies, the LC connector is one of the most commonly integrated fiber optic connectors due to its compact size. LC connectors measure about half the size of SC connectors (as discussed below) and were designed for high density deployments where multiple fibers terminate within a confined space.

With a square-shaped body and compact ferrule diameter of 1.25mm, LC connectors are found on most modern networking electronics, SFP transceivers, audio-visual electronics and patch panels. Two LC connectors are commonly bound together with a plastic clip to create a duplex connection.

- Known as the “little connector” or “lucent-style connector”

- 1.25mm ferrule size

- Snap-on type connection

- One fiber strand per connector

- Compatible with single mode and multimode fiber

- Commonly found on modern electronics, SFP transceivers, audio-visual extenders and patch panels

SC Connectors

Predating LC connectors, SC connectors were the predominant electronics fiber connector due to their convenient square shape and easy-to-terminate 2.5mm ferule size. While most devices have now turned to LCs due to their compact size, SC connectors are still widely used in broadband and patching applications thanks to their rugged construction and typically lower cost per connector.

SC connectors are typically found in outside plant, broadband and telecom applications, such as when wiring a modem or demarcation location. In these applications, one SC connector is often present (known as a simplex connection).

SC connectors are also still found on patch panels and interconnect hardware thanks to their cost and ease-of-termination. In these applications, two SC connectors are commonly bound together with a plastic clip to create a duplex connection. When used in patching, however, the SC connection is often adapted to an LC connection with a conversion patch cord.

- Known as the “standard connector”, “square connector” or “subscriber connector”

- 2.5mm ferrule size

- Snap-on type connection

- One fiber strand per connector

- Compatible with single mode and multimode fiber

- Commonly found on broadband internet devices (modems), outside plant connections, older electronics, some audio-visual extenders and patch panels

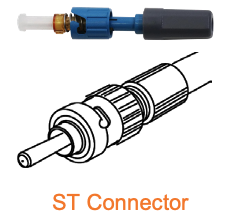

ST Connectors

ST connectors were one of the first connector types to be widely installed in fiber optic networking applications. Developed by AT&T, the ST connector features a twist-on bayonet design similar to a BNC video connection. For many years integrators appreciated the straight-forward, secure termination style; however, STs are harder to terminate in the field and have been largely replaced by LC and SC connections.

Like the SC connector, STs feature a 2.5mm ferrule.

- Known as the “straight-tip connector”

- 2.5mm ferrule size

- Twist-on type connection

- One fiber strand per connector

- Compatible with single mode and multimode fiber

- Commonly found on older electronics and older patch panels

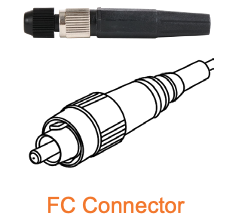

FC Connectors

Similar to the ST connector, FC connectors feature a round design with a 2.5mm ferrule. However, where ST connectors connect with a locking half twist, FC connectors screw on thanks to an overall threaded body.

Also like ST connectors, FC connectors are harder to terminate in the field and have been largely replaced by LC and SC connections. However, because of their durability, FC connectors still found on devices that require frequent connections and disconnections and applications with high vibration and motion.

- Known as the “ferrule core connector”

- 2.5mm ferrule size

- Screw-on type connection

- One fiber strand per connector

- Compatible with single mode and multimode fiber

- Commonly found in broadcast and testing electronics

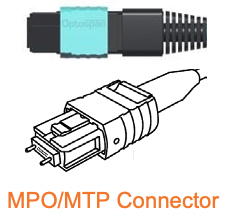

MPO/MTP Connectors

The final connectors on our list, MPO and MTPs feature a multi fiber design that’s perfect for high-density and extreme bandwidth environments, such as data centers and switch-to-switch connections. Up to 24 fiber strands are commonly terminated in a single compact connector, though strand counts up to 72 are theoretically possible.

Originally developed as the multi-fiber push-on (MPO) connector, US Conec improved the design renaming it the MTP. Today, both are found in 10G, 40G, 100G, 400G and 800G networks.

Unlike LC, SC, ST and FC connectors, MPO and MTP connectors are not typically terminated in the field. Instead, built-to-length patch cords are used.

- Known as the “multi-fiber push-on connector”

- Push-pull type connection

- Up to 24 fiber strands per connector

- Compatible with single mode and multimode fiber

- Commonly found in high-density applications such as data centers or in switch-to-switch connections

Other Connectors & Next Steps

The connectors described in this article are commonly found in network, internet, security, audio-visual and datacom applications; however, other fiber optic connectors do exist. MTRJ, MU, SN Compact and OptiJack are just some of the other varieties used in different environments and applications; though they tend to be specialized and not present in integration.

Future Ready Solutions offers the training, tools, testers and connectivity products to identify, install and troubleshoot fiber optic connections in the field. Please contact us at www.futurereadysolutions.com for additional information.